CLEARNESS 6 is our new sixth generation clarifying filter.

This highly practical and functional machine has been designed and constructed with the following specific aims in mind:

- Improving the efficiency of the filtration of extra virgin olive oil, clarified or raw, and all edible oils in general, before bottling, using carton pads or filtering sheets.

- Provide the user with a device that keeps the product (which is delicate and prone to absorb odours, tastes, etc.) isolated from contact with the external environment.

- Recover by physical means as much of the oil as possible, trapped by the carton pads of the previous filtration, without additional charges, without alteration of the product, on the same machine that made the filtering.

This change makes our machine even more efficient.

The pressing device for oil cartons, driven by an hydraulic station, enables:

- Recover immediately a fresh product, not aged and not oxidized, reducing oil leakage to a minimum, reducing filtration cost making the carton pads dry and easy to manage.

- To create a supporting structure completely of stainless steel with a high-capacity tank that is closed during filtration and an interlocking cover, which ensures the isolation of the filtering pack from the outside environment, thereby preserving the quality of the processing and constituting an essential hygienic element.

- To create a new, unique and completely innovative high efficiency filtering element, composed of polypropylene or stainless steel which allows the use of carton pads and/or filtering layers of any thickness, without problems involving gaskets or seals.

Thanks to the shape of these filtering elements, the size of the machine is greatly reduced, there is less leakage during operation and lower production costs.

It is possible to couple our filtering elements with carton pads or filtering layers of any thickness (from 350 to 1600 gr/m2), allowing the user to clarify oils that are already semi-refined or crude, which may contain humidity, impurities or waxes.

The choice of system and carton pads must be made in accordance with the type of filtration that is desired. The delivery capacities vary depending on the type of oil to be filtered, the carton pad or layers used, the filtration temperature, type of power supply to the filter, etc.

- To operate at the desired pressure, from a minimum of 0,2 to a maximum of 3 BAR (approx.)

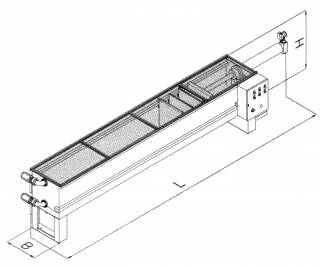

The standard machine in its semi-automatic version is composed of:

- A structure entirely manufactured of stainless steel containing a spacious tank for holding the entire filtering pack.

- A sliding cover, fitted on to the upper part of the structure.

- A filtering pack composed of polypropylene plates and carton pads or filtering layers.

- An hydraulic oil closing system complete with control unit, electric panel and automatic control.

- A device for pressing the carton pads.

- Two stainless steel valves.

- A clear indicator of passage.

- A stainless steel valve for the oil recovery from the tank.

- A pressure gauge.

- An electrical control panel.

For filtrations without retrieval of oil from the carton pads, the machine has a manual closing system with an hydraulic piston driven by hand pump and clamping screw closing.

Optional elements in the supply are as follows:

- A feed pump, fittings and tubing

- A compressed air generator

- Four pivoting wheels

| Model | Plates | Paper board | Filtering surface | Max pressure | Paper board press | L | H | B |

|---|---|---|---|---|---|---|---|---|

| CLEARNESS | N | N | m2 | mm | mm | mm | ||

| 320/30 HMB | 61 | 62 | 5 | 3 | NO | 1400 | 1100 | 500 |

| 320/60 HMB | 121 | 122 | 10 | 3 | NO | 1900 | 1100 | 500 |

| 440/60 HMB | 121 | 122 | 20 | 3 | NO | 2800 | 1100 | 700 |

| 440/100 HMB | 201 | 202 | 33 | 3 | NO | 3400 | 1100 | 700 |

| 440/150 HMB | 301 | 302 | 49,5 | 3 | NO | 4000 | 1100 | 700 |

| 440/200 HMB | 401 | 402 | 66 | 3 | NO | 4700 | 1100 | 700 |

| 440/60 HB+P | 121 | 122 | 20 | 3 | SI | 2400 | 1100 | 700 |

| 440/100 HB+P | 201 | 202 | 33 | 3 | SI | 3000 | 1100 | 700 |

| 440/150 HB+P | 301 | 302 | 49,5 | 3 | SI | 4200 | 1100 | 700 |

| 440/200 HB+P | 401 | 402 | 66 | 3 | SI | 5000 | 1100 | 700 |

| 625/160 HB+P | 321 | 322 | 100 | 3 | SI | 4500 | 1250 | 900 |

| 625/210 HB+P | 421 | 422 | 125 | 3 | SI | 5300 | 1250 | 900 |

All the measures are indicative and not binding. Galigani Filtri reserves the right to modify at any time without notice.